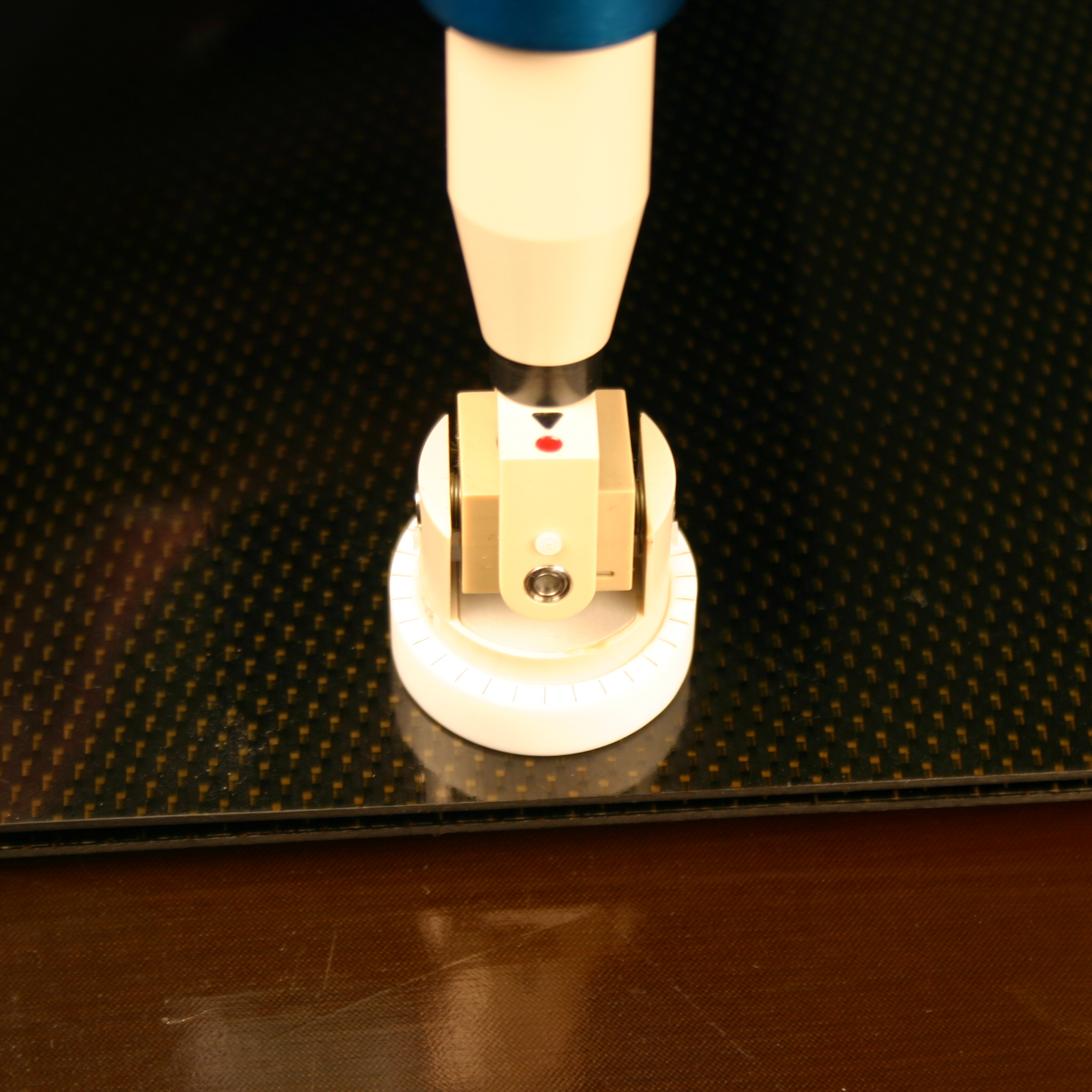

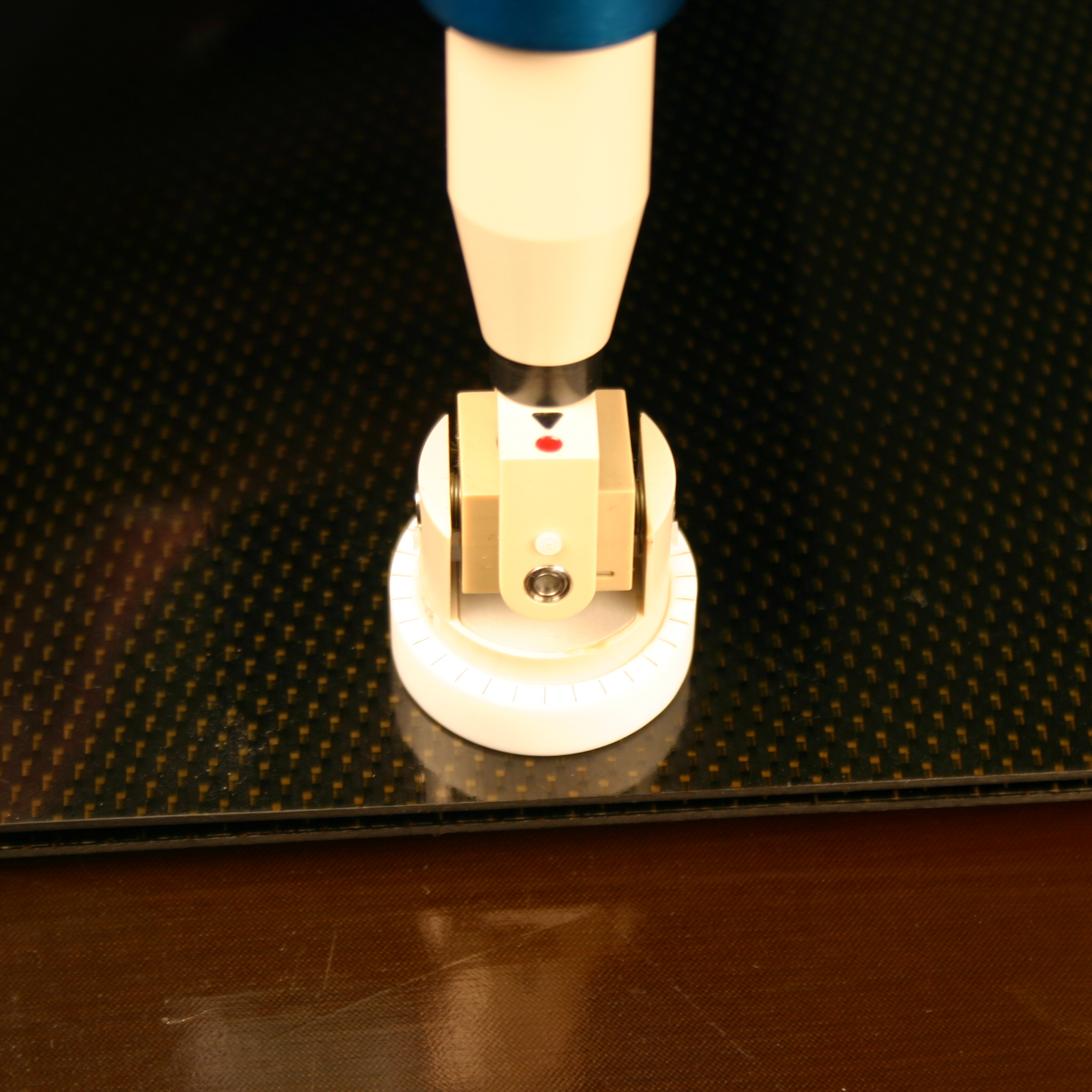

M-Wave Hand-Held Imaging System

Patented and Patents Pending

M-Wave technology leverages the sensitivity created in an LRC (inductance, resistance, capacitance) circuit when it operates at natural resonant frequency. M-Wave has a transmit coil and a receive coil, both of which are precisely tuned to not only to the electrical characteristics of the sensor and circuit but to the characteristics of components and materials being imaged.

This technology works at stand-off distances and is capable of imaging through multiple composite walls. M-Wave can detect many types of defects including FOD, delamination, porosity, impact and even kissing bond.

M-Wave can image through LO (low observable) coatings to inspect the composite substrate. This is especially useful when impact on leading edges or other coated areas occurs. This eliminates the need to remove and reapply coatings to inspect impact areas with traditional methods.

FOD and Flaw Detection

Detects paper and polymer FOD during manufacture.

Inspects uncured lay-ups, avoiding flaws before autoclave.

Finds delamination, porosity, impact and kissing bond.

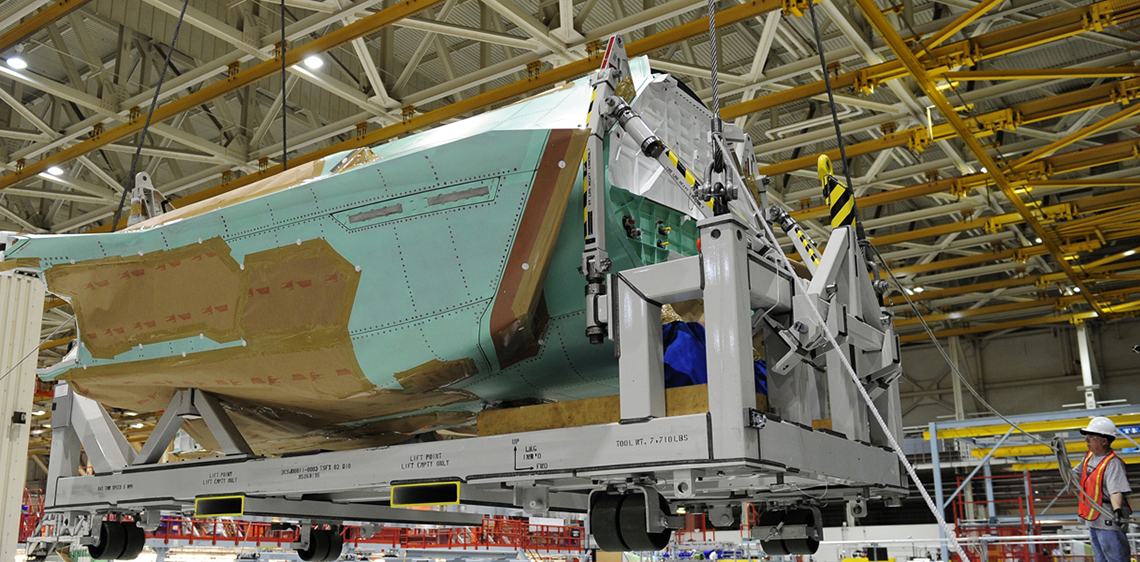

Detection Through Multiple Walls

M-Wave requires NO coupling fluid to operate.

Flaw detection at standoff distances and through multiple composite walls.

Flaw and substructure characterization.

Detection Through LO Coatings

Capable of imaging through LO coatings of all types.

Detects impact damage and other flaws through LO coatings.

Eliminates the need to strip and reapply LO coating after impact event.